Using nettle in bag manufacturing is a viable and eco-friendly option gaining popularity among manufacturers and designers. With a growing concern for the carbon footprint left by mass manufacturing, many are turning to both technological advancements and traditional methods to produce sustainable products. In this regard, nettle has emerged as a promising material for creating bags. As your guide, let me help you understand the benefits and process of using nettle in bag manufacturing.

Nettle possesses a remarkable array of properties and potential applications, from textile production to culinary and medicinal uses. Despite their stinging reputation, they have historically played significant roles in various cultures and continue to offer benefits today. Let’s explore how this eco-friendly option is gaining traction among manufacturers and designers, reshaping the fashion industry one bag at a time.

What is Nettle?

As a passionate advocate for both bags and sustainability, I’m excited to delve into the world of using nettle in bag manufacturing. So, what exactly is nettle? Picture this: a resilient, fibrous plant used for centuries due to its versatile nature. Nettle fabric boasts remarkable strength and breathability, making it a standout choice in bag manufacturing. But what sets it apart from its counterpart, ramie? While both plants share similarities in appearance, nettle fibers are finer and softer, making them ideal for crafting luxurious bags with a natural touch.

Differences and Similarities Between Nettle and Ramie

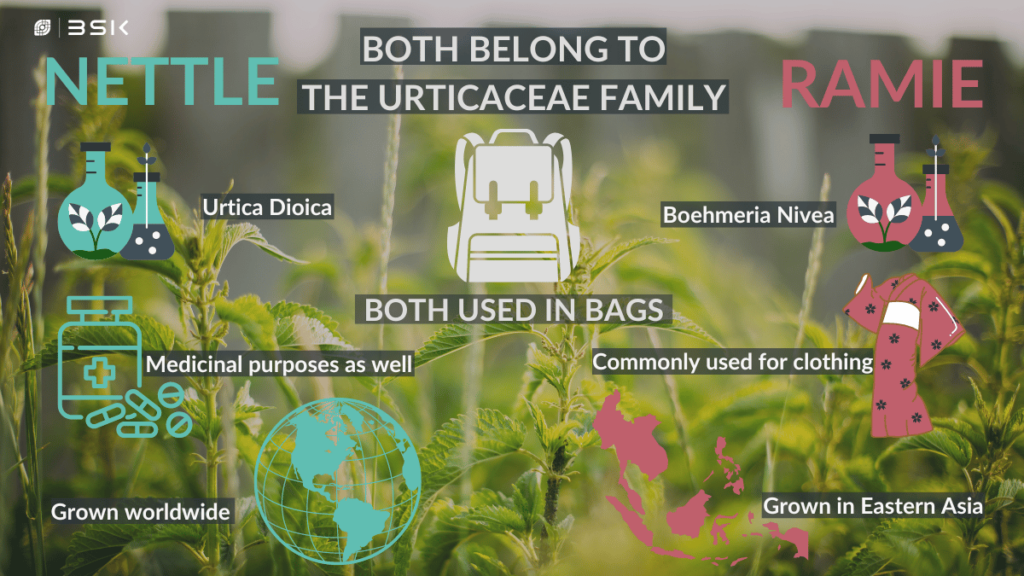

- Nettle (Urtica dioica) and ramie (Boehmeria nivea) are both fibrous plants used in textile production, but they have differences:

- Nettle is found worldwide, while ramie is mostly grown in Eastern Asia, especially China and Japan.

- Ramie fibers are strong, durable, lustrous, and even stronger than flax or hemp. They are absorbent and resist mildew and insects. Nettle fibers are coarser and less lustrous than ramie but still have good tensile strength. They are soft and comfortable, suitable for clothing and textiles.

The Medicinal and Cultural Significance

Beyond its utility in bag manufacturing, nettles have been used for centuries in herbal medicine to treat various conditions, including allergies, arthritis, and eczema. They are rich in vitamins A, C, and K and minerals like iron, magnesium, phosphorus, and potassium. Nettle leaves can be cooked and eaten as green leafy vegetables, which neutralizes the stinging chemicals, or can be dried and used to make tea. Beyond its use in traditional medicine, nettle is also used in cosmetics and textiles. Nettles were not just a significant culture. This magnificent plant played vital roles from the Romans to the modern-day herbalists, demonstrating its enduring importance and versatility. Its fibrous stems have been woven into fabrics, providing durable textiles for clothing and household items.

Recent Historical Use of The Stinging Nettle

Textile Substitute: During World War One, the nettle became a vital substitute for cotton in clothing and bag production using nettle due to shortages caused by blockades in Germany. Their fibrous stems could be woven into a thread of comparable quality to other materials like flax. The same was true for the Swiss during World War II, who were in short supply of cotton then, so they turned their attention to nettle fiber to produce bags for troops taking up defense positions on hills and mountains.

Recently, the perception of stinging nettle among farmers in Temal rural municipality Kavre has significantly transformed. Initially considered an unwanted weed, farmers are now capitalizing on its medicinal properties thanks to training provided by UNDP’s Community Infrastructure and Livelihood Recovery Programme (CILRP) and Temal Rural Municipality.

Through training sessions covering nettle leaf collection, drying, grinding, packaging, and business basics, local farmers, including women, have been equipped with the skills and technology necessary to turn nettle into a profitable enterprise. This initiative has provided economic opportunities and demonstrated nettle powder’s market potential due to its medicinal value. The eco-friendly nature of nettle cultivation, requiring no fertilizers or pesticides, aligns with sustainable farming practices, making it a green business. The success of this initiative has encouraged further engagement in nettle powder production, with local authorities pledging to promote eco-friendly farming practices in the community.

Advantages Of Nettle Materials

The utilization of nettle in bag manufacturing presents a plethora of advantages rooted in its exceptional properties. One of the most notable advantages is the nettle’s minimal water requirement, making it an eco-conscious alternative to water-intensive cotton. Additionally, Nettle fibers boast remarkable strength and durability, offering longevity and wearability to bag products. Its versatility allows seamless blending with other natural materials, such as cotton, hemp, and jute, enhancing the final product’s structural integrity and aesthetic appeal. Real-world examples abound, showcasing Nettle-based bags’ resilience and aesthetic appeal across diverse consumer demographics.

- Sustainability: Nettle plants are a sustainable resource, needing little water and no chemicals to produce eco-friendly fibers.

- Biodegradability: Nettle fibers are biodegradable and naturally decompose to lessen environmental impact and waste.

- Strength and Durability: Nettle fibers are softer than some natural fibers like ramie, but they are still strong and durable, making them ideal for creating long-lasting bags that can withstand daily use.

- Breathability: Nettle fibers are breathable, keeping bag contents dry and fresh.

- Versatility: Nettle fibers can be blended with other materials such as cotton, hemp, or recycled polyester to enhance their properties and create custom blends tailored to specific bag designs and purposes.

- Comfort: Nettle fibers are soft and comfortable to wear or use in skin-contact bags.

- Adaptability: Nettle fibers can be processed to create diverse textures and finishes for bag manufacturing.

.

Limitations Of Using Nettles In Bag Manufacturing

Using nettle in bag production has its advantages, but it poses some challenges. The bags might not be durable enough, especially in high-wear areas, which calls for careful design and reinforcement strategies to prevent wear and tear. While nettle is a sustainable option, it might not be cost-effective for brands on a tight budget. However, there are innovative ways of growing, processing, and manufacturing nettle that tackle these issues, making it easier for more brands to adopt it for bag production.

Nettle Production & Manufacturing Considerations

Navigating nettle-based bags’ production and manufacturing process requires meticulous attention to detail and specialized expertise. Each step demands careful consideration and adherence to quality standards, from harvesting and processing Nettle fibers to assembling and finishing bag products.

Specialized equipment and techniques may be necessary to extract, refine, and weave nettle fibers into functional and fashionable bags. Design considerations, such as stitching methods and finishing touches, play a pivotal role in ensuring the integrity and aesthetic appeal of the final product.

Retting plays a vital role in separating the fiber from the plant stem, involving two primary methods: water retting and dew retting. In water retting, a more controlled process, workers submerge the stems. Conversely, dew retting requires laying the cut stems on the ground for several days. Although both methods yield high-quality fibers, water retting tends to be more costly and potentially harmful to the environment.

Workers or machinery undertake decortication following the retting process to detach the fiber from the stem. Subsequently, the fibers are processed and spun into yarn, serving as the base material for producing various items, including fabrics.

Nettle Sustainability & Environmental Impact

At the heart of nettle’s appeal lies its inherent sustainability and eco-friendliness. Biodegradable and recyclable, Nettle fibers epitomize the principles of circular fashion, aligning with the industry’s shift towards sustainable practices. Certifications such as the Global Organic Textile Standard (GOTS) and OEKO-TEX Standard 100 underscore nettle’s eco-credentials, assuring consumers of its minimal environmental footprint. As the fashion industry embraces sustainability, nettle emerges as a frontrunner in eco-conscious bag manufacturing. Offering brands a tangible pathway towards reducing their ecological impact and promoting ethical production practices.

In conclusion, the utilization of nettle in bag manufacturing signifies a paradigm shift towards sustainability and innovation in the fashion industry. Despite inherent challenges, the benefits of nettle far outweigh the limitations. Offering brands an opportunity to redefine their ethos and cater to increasingly eco-conscious consumers. By harnessing nettle’s resilience, versatility, and eco-friendliness, fashion brands can spearhead a movement towards greener, more ethical bag manufacturing practices, ensuring a brighter and more sustainable future for the industry and the planet.