Many factors go into a bag’s design, but few carry as much weight as the fabric. While finishes and hardware are important, it’s the fabric that will determine the bag’s quality, durability, and appearance. Any skilled bag manufacturer will know just how important it is to spend time researching fabric details before diving into the creation phase. This step will set you up with the right foundations for success. If you’re seeking a fabric that exudes a timeless appeal while boasting impressive levels of durability and versatility, denim will likely be the perfect choice for you. In this comprehensive guide, we’ll provide you with the essential facts about using denim in bag manufacturing. Read on to find out if it’s the right fabric for you!

What is Denim?

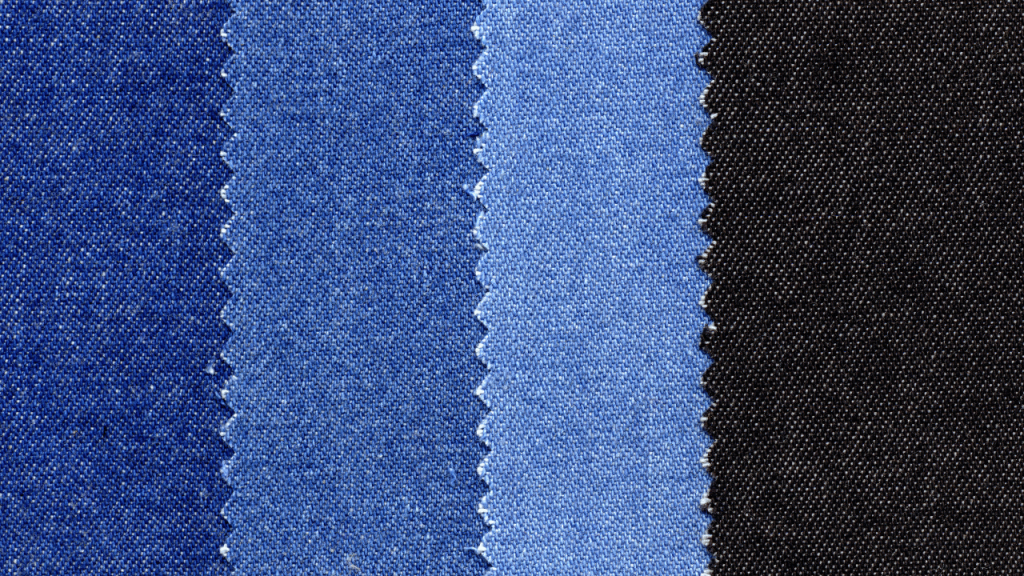

Denim is a sturdy cotton twill fabric known for its fine diagonal ribbing, also known as the “denim weave.” It is made using different colored warp and weft threads, typically blue, gray, or white, which help create its distinct appearance.

Now one of the most popular fabrics in the world, denim was originally used for workwear due to its durable nature. Its name derives from the French town of Nimes, where the fabric is believed to have originated. Over time, denim has become a global fashion staple and is widely used in the making of clothing and accessories, including bags.

The Advantages of Using Denim in Bag Manufacturing

Durability & Longevity. Denim is renowned for its exceptional strength and durability. Bags made from denim can easily endure the rigors of daily use, maintaining their structure even when carrying heavy loads. Denim’s strength makes it an ideal choice for bags and backpacks designed to carry books, laptops, or other items that require extra protection.

Timelessness. Denim’s classic and versatile aesthetic makes it a timeless fabric in the fashion world, and its popularity has steadily increased with time. Its universal appeal ensures that bags will stay fashionable regardless of changing trends. No matter which aesthetic your brand caters to, denim can effortlessly complement a wide range of designs.

Versatility. Denim can be created with a broad spectrum of finishes, including distressed, stone-washed, acid-washed, or raw. Each finish adds character to the bag, allowing designers to create unique styles and cater to diverse consumer preferences. Denim can also be blended with other materials, such as leather or canvas, to create eye-catching design combinations.

Easy Maintenance. Denim’s practicality extends to its ease of care. Bags made from denim can generally be machine-washed (depending on fabric blends and hardware elements) and are resistant to shrinking and wrinkling. This convenience makes denim bags an excellent choice for those seeking low-maintenance options.

Limitations of Using Denim in Bag Manufacturing

Weight. Denim tends to be heavier than other materials commonly used in bag manufacturing. While this weight can contribute to its durability, it may not be suitable for all bag styles or consumers looking for lightweight options.

Limited Color Range. Denim is most commonly associated with shades of blue, though it can also be created in black, gray, and white. While this color range is flattering and widely coveted, bag manufacturers seeking a broader selection of colors may find denim limiting. Fortunately, dyes and washes can be applied to denim to expand its color options, resulting in bold hues that rival other fabrics that are easily dyed.

Denim Production & Manufacturing Considerations

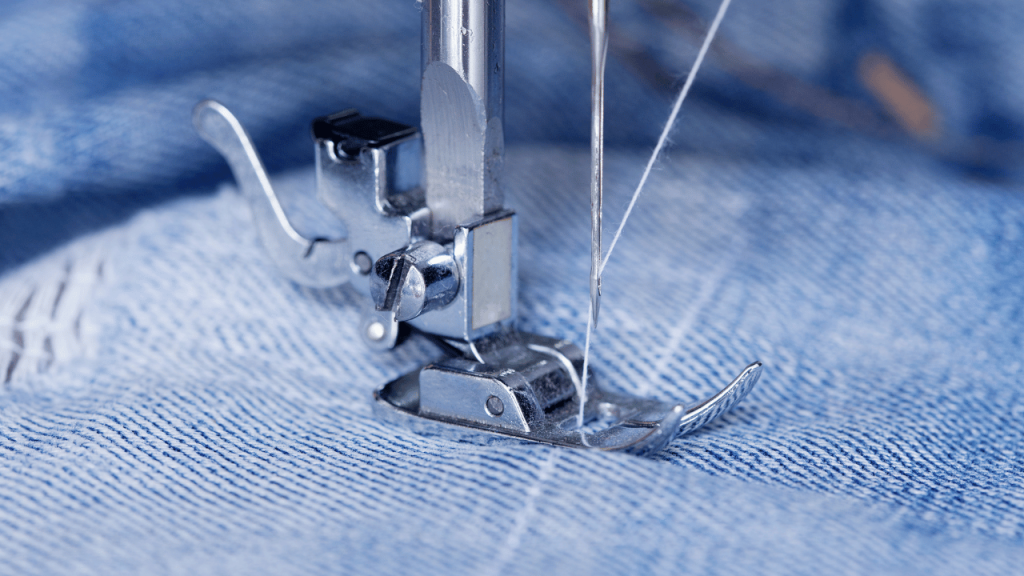

Denim fabric is typically made from cotton, and its production involves spinning cotton fibers into yarns, dyeing the yarns, and weaving them into denim fabric using specialized looms. Shuttle looms are recommended, as they ensure a smooth yet strong edge.

Aside from finishes that influence the aesthetic of the denim, manufacturers can use techniques such as brushing and thermo fixation to increase softness and stretch within the fabric.

Denim’s weight should always be taken into consideration during the production process. The fabric can be sewn with regular equipment, but specialized fabric cutters and sewing machines will work better to create more precise and durable stitching.

Denim Sustainability & Environmental Impact

Denim is a natural fabric, but its cultivation and production traditionally come with a negative environmental impact. It’s known to need high levels of water consumption, chemical usage, and energy requirements.

Cotton is a crop that requires extensive amounts of irrigation. It’s estimated that it takes over 3000 liters of water to create a single denim garment and around 33 kg of CO2 is released over its lifetime. The cultivation of cotton and the creation of denim is also tied to toxic pesticides, fertilizers, and dyes that seep back into the environment. These chemicals are also known to negatively affect the health of cotton farm workers.

While conventional denim does come with a fair share of environmental concerns, many industry players have been working on solutions to improve denim’s sustainability in recent years.

Bag manufacturers can negate the detrimental environmental impacts of denim by opting for organic cotton denim. This is grown without synthetic pesticides or fertilizers and requires significantly less water to grow than conventional cotton since it is cultivated with the use of rainwater rather than complex irrigation systems.

Conclusion

Recycled denim is another excellent option that eliminates the need for virgin resources. When it comes to finishing, manufacturers can employ eco-friendly dyeing processes, as well as investing in energy-efficient equipment. With its timeless appeal and elevated durability, denim offers numerous advantages for bag manufacturers. It’s a material that creates designs that will stand the test of time, both in terms of quality and style. Although denim has a few limitations, it’s guaranteed to remain a popular fabric within the fashion world. By carefully considering sourcing practices, adopting responsible manufacturing techniques, and exploring eco-friendly alternatives, bag manufacturers can maximize denim’s potential while minimizing its environmental impact.

You might also like: 6 Interesting Bags Fabrics You Must Know About