Whether you’re a budding bag designer or you work on a production team, you’ll know that a bag’s material is crucial to its success. It serves as the foundation of any design, determining its overall quality, strength, and aesthetic. Before creating any bag, it is essential to conduct thorough research and carefully consider materials to ensure you select the ideal one for your project. One material that you may want in your arsenal is polyester, the world’s leading synthetic material. This article will cover everything you need to know about polyester for bag manufacturing, helping you determine if it’s the right fit for your needs.

What Is Polyester?

The fashion industry and beyond widely use polyester, which is a synthetic fiber. It essentially derives from petrochemicals through a process called polymerization and represents a type of plastic. Polyester fibers are made by combining chemicals, creating long chains of polymer molecules that turn into a smooth, shiny, and durable fabric. This versatile material offers several benefits for bag manufacturing due to its unique properties, which we will now outline.

The Advantages Of Using Polyester In Bag Manufacturing

- Durability & Strength. Its exceptional strength and durability have earned polyester a renowned reputation. Due to the almost unbreakable weaves of the polymer molecules, items made from polyester can easily withstand everyday wear and tear. The material resists stretching, staining, shrinking, and wrinkling, ensuring that bags maintain their shape and appearance for years to come.

- Versatility & Aesthetics. Polyester offers immense versatility in terms of design possibilities. It facilitates easy dyeing, enabling the creation of bags in a rainbow of vibrant colors. The transformational qualities of polyester allow it to mimic the look and feel of other materials, such as silk, making it a popular alternative to more expensive materials.

- Water Resistance. One of the most noteworthy advantages of polyester is its inherent resistance to water. Polyester has moisture-wicking properties, which means that it offers protection against moisture and can dry quickly. The water resistance of polyester can be further enhanced through additional treatments or coatings. You’ll often find outdoor and travel bags made from polyester for this reason.

- Affordability. Compared to many other options available for bag manufacturing, polyester stands out as a cost-effective material. Its production processes are efficient and relatively inexpensive, resulting in bags made from polyester is more affordable for consumers without compromising quality.

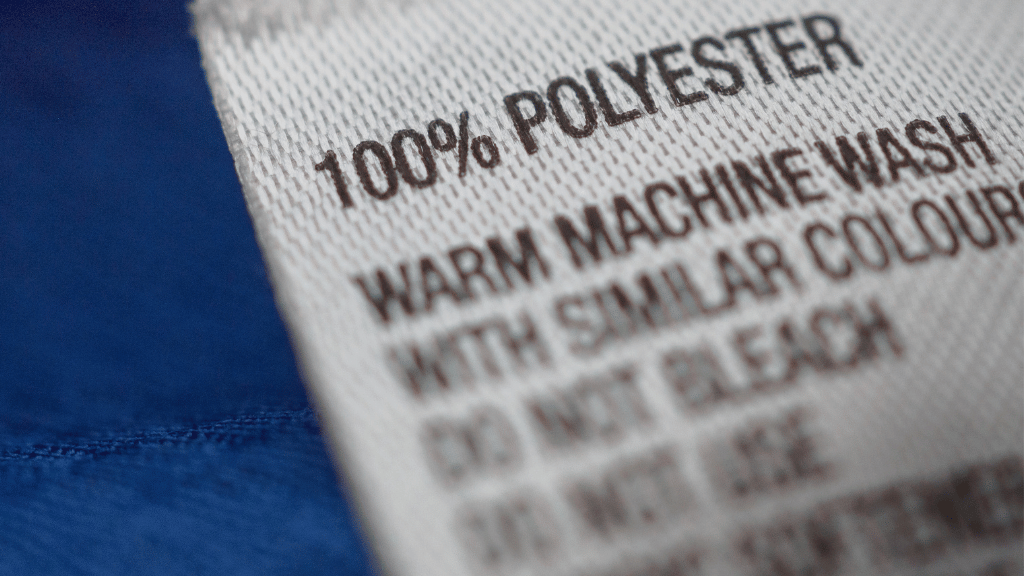

- Easy Maintenance. Polyester bags are low-maintenance and easy to clean. Busy individuals who value hassle-free bag care will find polyester bags suitable, as they offer the convenience of being machine washable or easily wiped clean.

Polyester’s resistance to wrinkles and shrinking simplifies the maintenance process even more. This ensures that bags maintain their shape and texture over time with guaranteed ease.

The Limitations of Using Polyester in Bag Manufacturing

- Breathability. Polyester is not as breathable as natural materials such as leather or cotton. Bags made from polyester may not offer the same level of ventilation, potentially leading to moisture build-up inside the bag. A strategic bag design that incorporates ventilation features offers an easy solution to mitigate this issue.

- Flammability. Polyester is a flammable material. Manufacturers and bag owners alike must take care to ensure their bags are never within close proximity to a fire.

- Environmental Impact. Concerns about the environmental impact of polyester arise from its derivation from petrochemicals. However, eco-friendly alternatives such as recycled polyester exist, helping bag manufacturers alleviate the environmental concerns that come with polyester.

Polyester Production & Manufacturing Considerations

Specialized cutting tools, such as sharp blades or rotary cutters, are essential for achieving clean and precise cuts, maintaining the fabric’s integrity, and ensuring accurate sizing. Sewing machines equipped with features suitable for polyester, such as Teflon-coated or roller presser feet, are recommended for bag manufacturing to reduce friction, prevent sticking, and create smooth stitching. Polyester-specific needles and thread are also a must to avoid damage and skipped stitches while ensuring secure seams that can withstand the strain bags may endure during everyday use.

Polyester Sustainability & Environmental Impact

The sustainability and environmental impact of polyester have been subjects of concern within the fashion industry in recent years. During its production, polyester consumes fossil fuels and releases greenhouse gases, contributing to climate change.

Despite the aforementioned concerns, certain forms of polyester can indeed be considered environmentally friendly. Advancements in manufacturing techniques have led to the development of recycled polyester, also known as rPET. This form of polyester is made from post-consumer plastic bottles and other recycled materials. It helps to reduce the reliance on virgin materials and to divert waste from landfills.

Additionally, polyester’s durability, longevity, and moisture-wicking properties play a significant role in its sustainability profile. Polyester bags can last up to 15 years with proper care, which gives them a healthy lifespan and reduces the need for frequent replacements. The material’s ability to quickly wick away moisture and resist stains means that the need for washing tends to be lower, and requires less water and energy than other fabrics.

Bag manufacturers can minimize the negative environmental impact of polyester by using recycled varieties, adopting eco-friendly production practices (including optimizing energy and water consumption, implementing efficient waste management systems, and ensuring responsible chemical usage and disposal), and promoting conscious consumption through the design of high-quality bags.

Conclusion

Polyester offers numerous advantages that make it an excellent choice for bag manufacturers. Its durability, versatility, affordability, and water resistance make it suitable for a wide range of bag types, from everyday backpacks to travel duffels. Thoughtful design and sustainable manufacturing practices provide effective solutions to address the challenges posed by polyester in terms of breathability and environmental impact. Whether it’s a trendy backpack or a chic tote, polyester has what it takes to make your bag designs a success.